Jay Patel’s Royal Enfield GT 535, Metal Jacket project.

Build Name – Metal Jacket

Donor Motorcycle – Royal Enfield Continental GT535 2014

Build Duration – 4 Months

The Royal Enfield Continental Gt 535 is the motorcycle very close to my heart and there are few reasons behind it

1. First it’s a highest capacity motorcycle I have ever worked on,

2. Second this is my 3rd project based on GT535,

3. Third reason is, I have introduced a bolt on kit fairing for GT535 for the very first time in India few years back.

So I am kind of very connected with this motorcycle and I always thought to do a build out of it which can hit the apex with its shape and stance using & enhancing all its performance capabilities.

So Overall idea behind the build was to build a motorcycle with sharp lines & shapes with aggressive & lightweight aluminum bodywork. Thinking of something futuristic as well as reflecting the era of retro racing motorcycles.

As I do everything on my own, it was my first experience to Shape major parts of this build out of aluminum. I’ve made aluminum tanks before but not the complete bodywork of motorcycle & it was learning experience for sure which enhanced my capabilities to work with aluminum.

I have begun the build sorting out the stock frame first. The frame is cut down from rear and only piece used of stock frame is the one holding the engine. Before heading to creating other half of frame I started creating wire-frame of tank first along with rear cowl & seat lines to decide overall stance of the bike and start shaping actual parts As I really wanted to focus only on shapes and stance of the motorcycle.

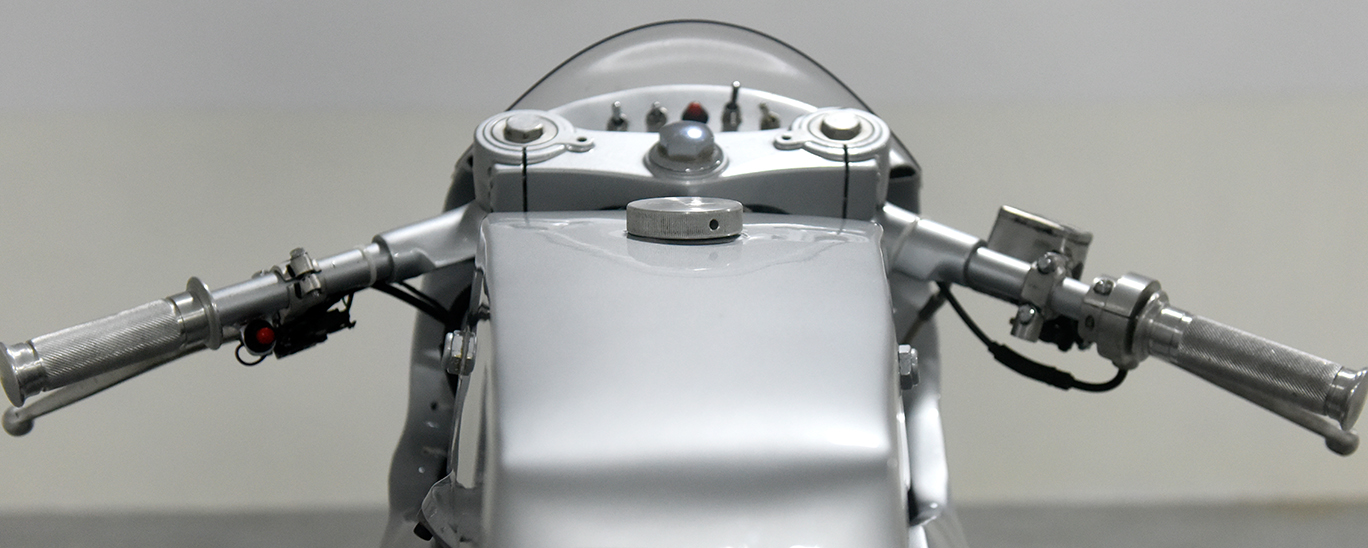

I tried to create kind of a 3d type shape with the tank and rear cowl which you can observe at the bottom line of tank continuing to cowl. The tank is made out of 1.5mm aluminum & can hold around 14liters of fuel. You can see sight glass as a gauge on both the sides of tank to check the fuel level. I got that idea from air compressor oil level sight glass & managed to make it possible for the fuel tank. Fuel cap is also made out of aluminum with the threads and no lock or key to keep it simple with the J&D logo engraved.

Before building rear swing arm and shock absorbent setup I shortened front forks by 2 inches to achieve the perfect lines of retro racing motorcycles. The rear swing arm is hand built by me out of mild steel pipes with the change in length as well as design to enhance overall design. Though rear shock absorbent are the stock ones and many suggested during the build that I should switch to mono-shock but I was just in love with overall design using those stock ones and I thought everyone is using mono-shock these days and its very common setup so I decided to keep it this way creating new rear section of the frame with shock absorbent mounts, and as I did not wanted to show any of the rear frame pipes, the shape of seat pan and rear cowl help that out hiding the pipes. Rear cowl is actually detachable and seat is extended to end of the frame so anyone can sit as a pillion.

Coming to the most attractive part of build which is Fairing, its made out of 1.5mm aluminum sheet. I’ve made it in three pieces, two sides and one front and now all the three welded together and its one piece fairing now. I wanted to add some old school charm to the fairing so you can see aluminum riveting on edge of side panels as well as louvers done on both the sides. The top of the fairing is equipped with all the handlebar switches using toggle and push button switch which surly looks like salt racer bike cockpit. The small windscreen you can see is actually a Royal Enfield Helmet Visor I used as windscreen which I thought going pretty good while looking at the aerodynamics of design. All the electric components of motorcycle are relocated underneath the fairing and in front of engine. Have made Stainless steel pipes setup for the sensor cables of throttle body going underneath the tank to give the overall design a very raw look.

Handlebars and levers are stock but throttle assembly, hand-grips, footrests are made out of aluminum with knurling pattern.

Exhaust is completely made in-house out of 304 stainless steel tubing and elbows. Kept that in very raw form to enhance overall silver paint of bike. High performance K&N air filter is used to improve engine performance.

Both the wheel assemblies are stock. Hubs, rims & spokes are polished in matte finish.

Seat is very simple form of single layer of Dunlap using plain black leather. As I really don’t wanted to do any patterns and break the simplicity of the build.

The name of the build is Metal Jacket, as it’s a combination of materials like Aluminum, Mild steel and stainless steel and the front fairing referred to the Jacket of the bike putting out strong statement of macho personality.

So this build may or may not in the interest area of everyone but as a bike builder it was my dream to create the GT535 in these shapes and lines & I am really glad I got the client who gave me an opportunity to build it as per my vision and results are quite satisfying for me at least.

Courtesy to my colleagues to make my work even better!

Photography Courtesy 1) Indoor Shoot – Fanil Pandya ( http://www.fanilpandya.com/ )

2) Outdoor Shoot – Harshil Majmudar ( https://www.harshilmajmudar.com/ )

My Social Media Links – 1) Instagram – https://www.instagram.com/jdcustomco/

2) Website – www.jdcustomco.com